Robot Programming

We’ve programmed hundreds of robots in many different applications for customers across the United States, Mexico, Canada, and even a few in Europe. We’re happy to travel where ever you are to help out.

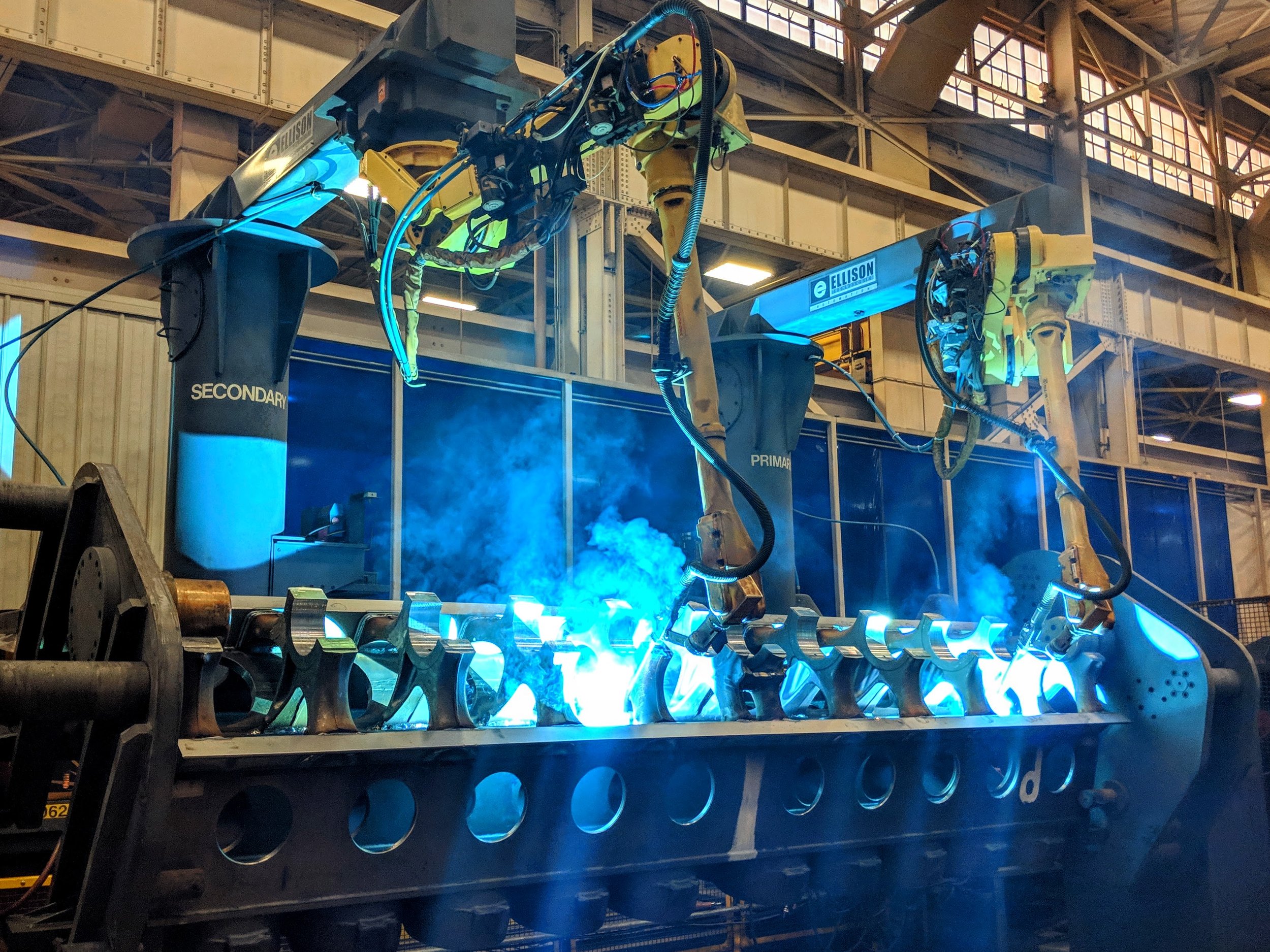

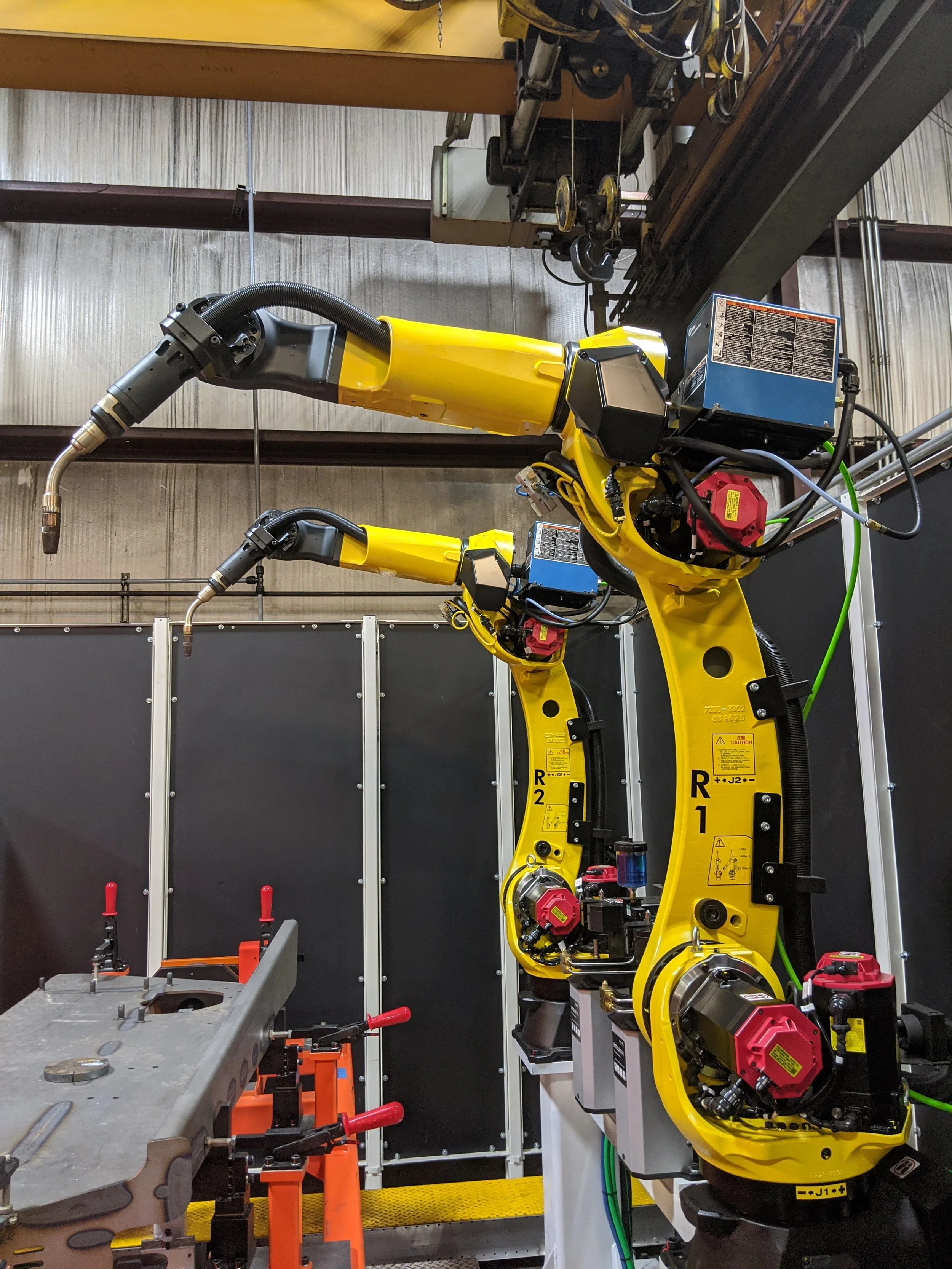

Welding applications are what we do best and will continue to excel where other people with less experience can struggle. We can set up the robots and welding equipment quickly and with very few setup parts.

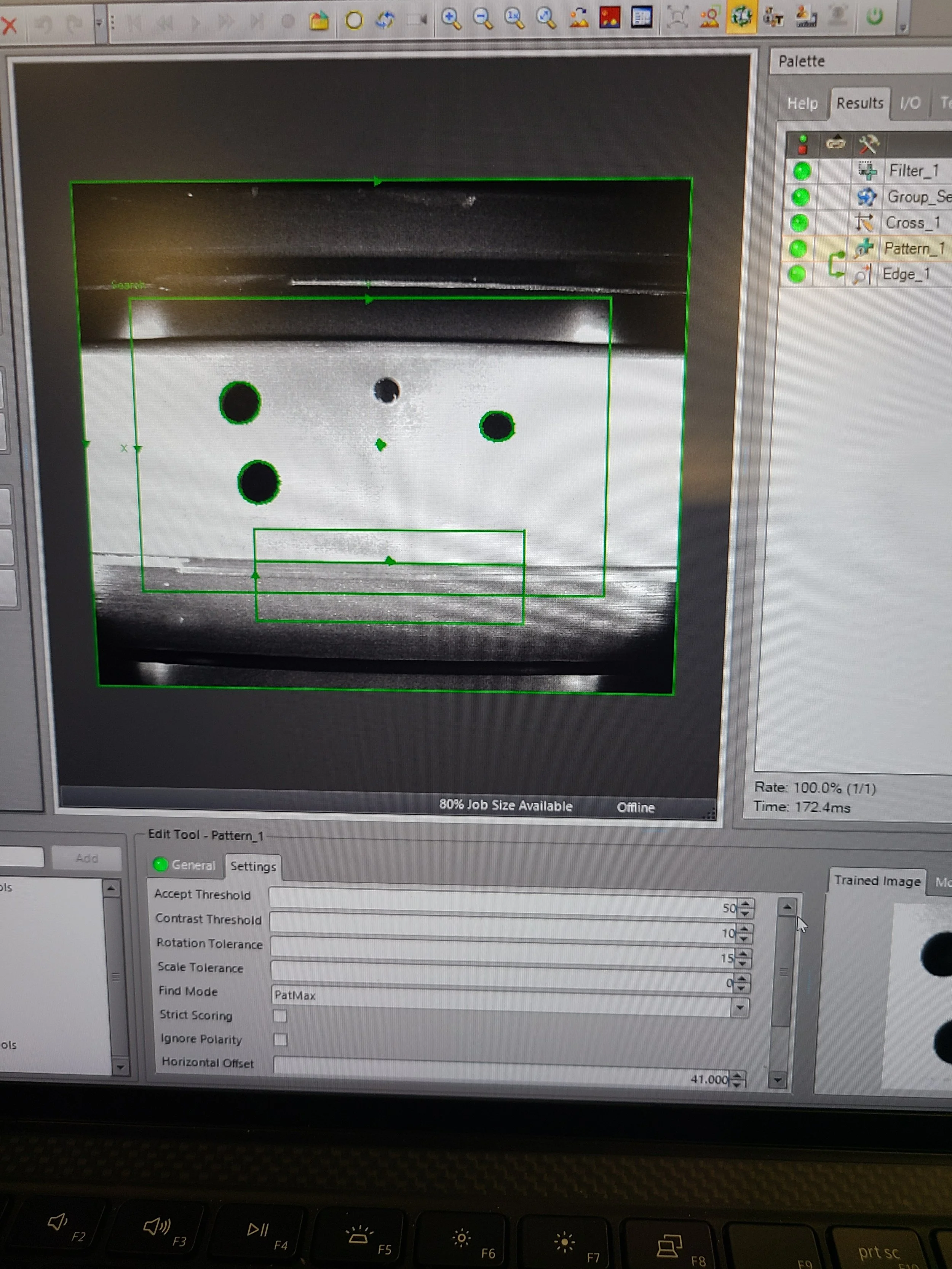

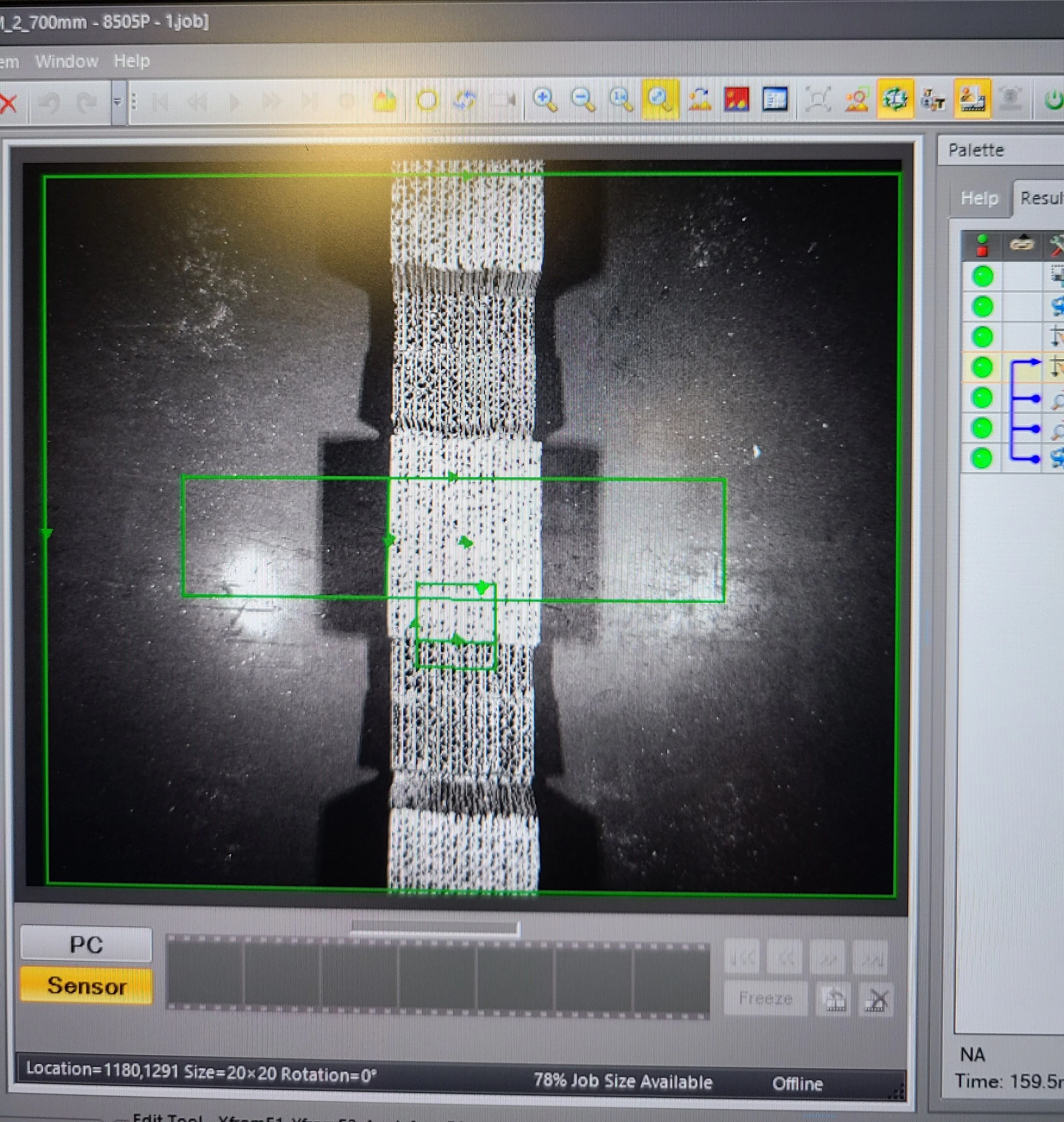

We specialize in difficult applications where advanced technologies must be used. Wire touch sensing, laser touch sensing, vision-based joint detection, through-arc seam tracking, real-time laser tracking, tandem wire welding, twin wire welding, coordinated motion with external axes, simultaneous robot welding, and multiple-pass welding are things we’re very familiar with. You don’t need to give the robot perfect parts if you let technology help the robot adapt to the variation that common in all manufacturing processes.

We’ve worked with numerous different applications over the years. Spot welding, GMAW (MIG) welding, GTAW (TIG) welding, projection welding (RPW), Capacitive Discharge Welding (CD Welding), Plasma Arc Cutting (PAC), material handling, press tending, adhesive dispensing, riveting, and sawing. If you have something else you want us to work on, we’re always up for a new challenge.

Reducing cycle time is a huge part of what we do. Whether you’re tired of working weekends trying to keep up with your customer’s orders or just want more parts out per shift, we can help make that happen. Sometimes we can easily cut seconds at a time, while other times we have to really work to eliminate fractions of a second in many places throughout the cycle to squeeze out every bit of time. The results are very rewarding as employees can often get some much-needed time off and management loves the increased efficiency and not having to pay overtime rates.