Welding Engineering

Welding Engineering starts at the concept of the product. There are many things that need to be considered in how a part is designed and built so that it can be welded successfully, both in automated and manual applications. We can help you design your parts so they are less expensive to manufacture, easier to weld and more repeatable.

The involvement of a Welding Engineer during the design of the fixtures that will tack and hold the parts during welding is also critical. Weld quality should never be sacrificed because the tool designer doesn’t understand the fundamentals of welding and is unintentionally making it difficult to reach the welds. We can work with your engineers to ensure that the fixtures are easy to load and unload, the part is held properly and repeatably, the fixtures provide the required access for successful welding, and your part wills will be dimensionally repeatable.

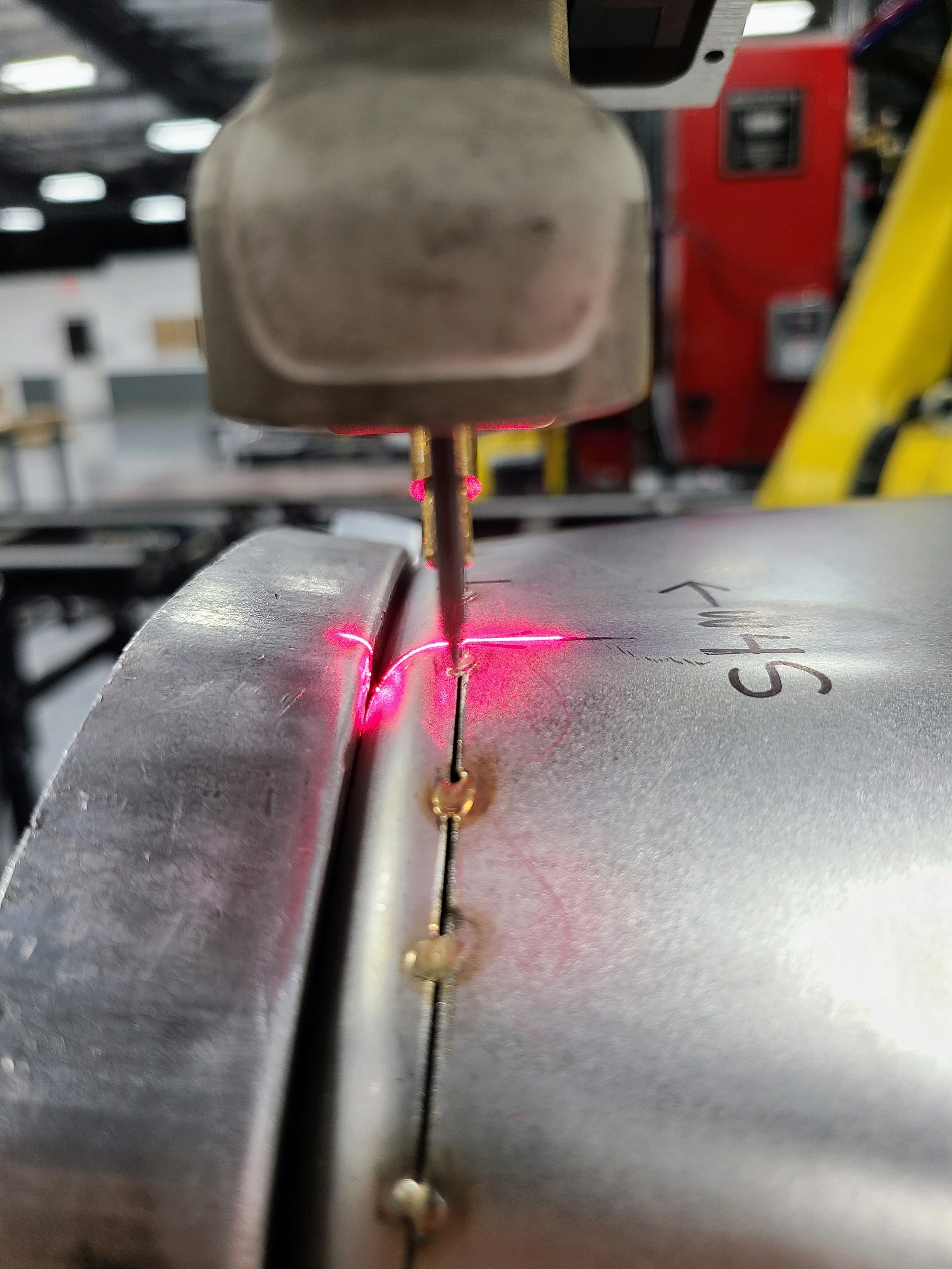

Having the right weld equipment is critical to successful welding. There are many different welding power supplies, wire feeders, torches, coolers, reamers, and consumables available, and they will NOT all perform equally. With over 30 years of experience working with much of the equipment on the market, we can help you choose the equipment that will work right the first time.

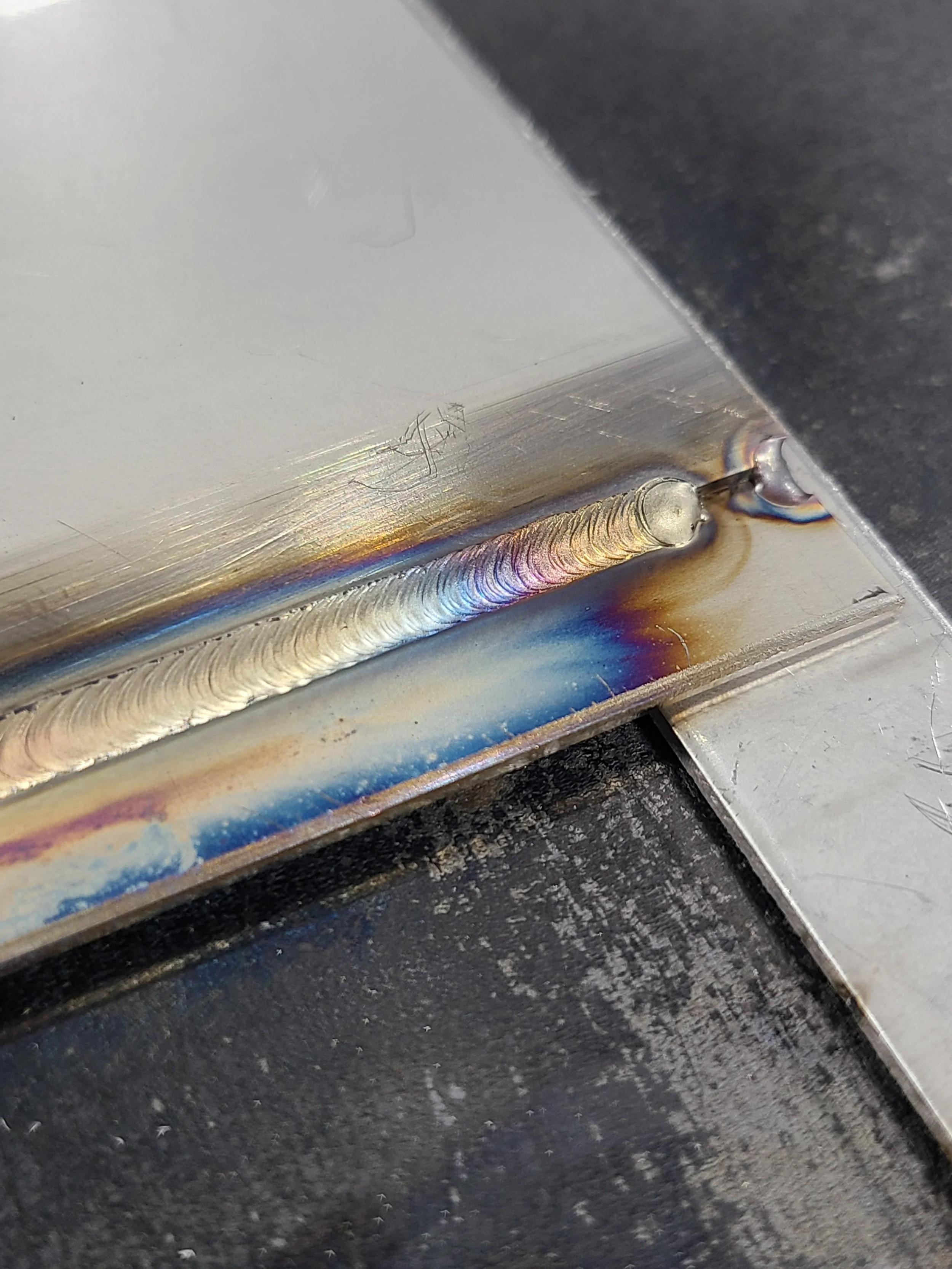

Making welds as quickly as possible while still maintaining the required level of quality is the key to meeting production demands and being profitable. The time it takes to perform the weld is typically the majority of the cycle time in manual and automated applications, so it’s critical that the weld process be as optimized as it can be. We can help you set up a weld process that will ensure repeatably good weld quality with little to no rework or scrap and meet your cycle time requirements.

Using a properly qualified procedure and validating your weld quality both before production starts and on a regular schedule after production is at peak volume is not only required by most customers, but it also protects manufacturers from potential quality problems. We can help develop your quality assurance processes per American Welding Society (AWS) or other specifications. We can help you source the equipment and train your people to test the quality of your welds on a regular basis.